Part 1

Are you considering starting a new food manufacturing business? Then a lot of help is available to you. This can be for the marketing, product and packaging design, advice on the financial aspects and the tax implications. Often overlooked are the key technical aspects of starting a food manufacturing business.

In this post we explore the technical issues that every food manufacturing business must be aware of. No matter what type of product you are making or planning to make. No matter how simple, or complex your process is, these are issues that you must be able to deal with. These are the Food Business Essentials.

To help with understanding these technical issues FBA has developed Food Business Essentials. An extensive range of 1 hour Webinars that focus on specific topics, providing the essential nuggets of information in bite size pieces.

You can select the webinars you need to gain the knowledge needed to progress your business in the right direction.

What are these essential topics that you need to be familiar with?

Part 1

Part 2

- Date Coding

- On-Line Selling

- Nutrition Claims

- Health Claims

- Making Free From Claims

- Nutritional Information

- MAP & Vacuum Packing

Food Safety

Every food manufacturing business needs to have food safety at the core of its activities. To achieve this you need to have good understating of your obligations under the General Food Hygiene Requirements for Businesses. Therefore participating in a Level 2 Course in Food Safety is one of the best ways to achieve this.

A tutored course will give you so much more than the on-line alternative. It will deliver discussion and interaction that is not available on-line.

The Level 2 Award in Food Safety is the minimum when starting a new food business. However as a business owner we would recommend the Level 3 Award in Food Safety.

With regard food safety you need to understand your obligations as a business owner. Should you have employees then you need to know what their responsibilities are. All food handlers need to be supervised and instructed or trained. So Show are you going to ensure you meet that obligation? A formal accredited course is suitable evidence of training.

The Food Safety course would require in several sessions to communicate the essential information if split into webinars. So we recommend the tutored courses for this topic.

HACCP

HACCP is the key element of the food safety plan. In effect it is the starting point for all the food safety controls you put in place.

General Food Hygiene Requirements for Businesses requires that every food operation has in place a permanent food safety plan based on the HACCP principles. There is a great deal of advice and support available for developing and implementing the HACCP plan for a business. However the regulation requires that those responsible for the operation of the plan have received “adequate training in the application of the HACCP principles“.

This means that even If you have your HACCP plan written for you, you are still responsible for the management, monitoring and controls that are put in place.

Essentially HACCP is not a stationery control it must adapt and develop as your business and products change. This means that as the business owner you need to understand how to make those changes, when they are needed and how to record them.

The complex and extensive nature of HACCP means the topic is not suited to short webinars. We would encourage business owners to participate in a Level 2 HACCP course. However a Level 3 course would provide an even greater level of understanding.

Allergen Management

Whether your business handles allergens or not you should have some understanding of allergen management. The Food Standards Agency recommends that all food handlers receive some training in allergen management. Therefore we have developed a 1 hour webinar to provide a summary of allergen management. When starting a new food manufacturing business you should ensure you have a basic understating of allergen management.

Many business owners are familiar with the cross contamination risk from raw to cooked but can overlook the risks from allergens. As a business owner do you really know what allergens are in your products? Do you know what allergens are in your ingredients?

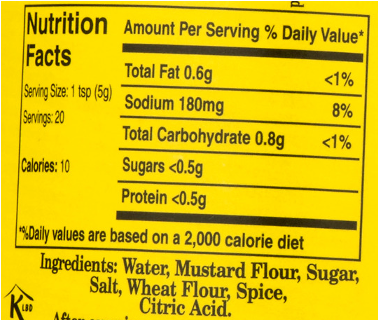

You know mustard is an allergen, but do you know whether or not your mustard contains wheat flour?

Many product recalls in the UK are as a result of poor allergen management and awareness.

This is a risk you do not want to take and can avoid. Therefore take the time to understand what allergen management entails. You can put in place the correct procedures and safeguards. These will protect your customers and therefore protect your business.

We would suggest that you, at least, take some basic training familiarise your self with the issues surrounding allergens. For business owners who make products containing allergens then the Level 3 Award in Allergen Management provides a more comprehensive discussion of the topic.

Food Labelling

The obligations on a business for food labelling are set out in the Food Information for Consumers Regulations. Therefore every business owner needs to understand the mandatory labelling requirements and how they relate to their products.

Are you confident are you your ingredient declarations are correct?

Do you understand what QUID is and if it relates to your ingredient declaration?

One of the most common causes of product recalls in the UK is incorrect labelling of allergens. How do you identify and label your allergens?

No matter what size of business or production process the rules on mandatory labelling apply to all. A small artisan producer must provide the same information to the consumer as a large processor. In other words no matter who makes the product the consumer has the right to certain information.

Every business owner needs to be confident their labels are correct, complete and above all are not misleading. When starting a food manufacturing business you should take the time to understand with the mandatory requirements. To assist with this we have developed a 1 hour webinar that explains the mandatory labelling requirements. A more in depth exposure to the subject can be found with the Level 2 Award in Food Labelling.

Traceability

Every food business must be able to trace where all their ingredients have come from. They must also be able to show the other businesses to whom they have supplied products. In other words you must be able to trace your products “one step up” and “one step back”.

The general food law regulation sets out what is expected from a business. The key test is that when challenged by an enforcement officer you are able to produce all the relevant records. Therefore you must not leave it to chance that your records are sufficient. You need to document where your ingredients come from, any alternatives that you have. Record which ingredient from which supplier was used in each batch of product. Finally to which business each batch of product was sold. This will give you “end to end” traceability within your operation.

Traceability systems do not have to be cumbersome and time consuming. With some careful though you can use them to help your business. Your records will show what you have used, how much and where. From this you can identify any over or under usage, it help identify waste and reduce cost.

Above all traceability records ensure you meet your legal obligations but they also help control costs and manage waste.

Calibration

Often overlooked as part of the manufacturing operation calibration is very important.

It can be part of a number of operations. You need to calibrate the equipment that is used for essential measurements. Without regular calibration how do know your readings are accurate?

When using scales for weighing products the Weights & Measures Regulations require you to show the equipment is suitable. You can do this by regularly checking the reading against calibrated weights.

Temperature measurements can be vital for some operations. The Food Hygiene Regulations set out maximum temperatures for chilled products. As a result you need to be confident in the readings from your temperature probe. As a business owner you need to be sure your measuring equipment is capable of the task. Regular calibration of the probes is an important task. You can achieve this by sending the equipment away to a specialist company. Whilst effective it can be expensive. There are simpler more practical options that can give the control but at a lower cost.

The General Food Hygiene Regulations require that monitoring of your CCPs is effective. You therefore need confidence in your measuring equipment. Regular calibration identifies any problems and gives you that confidence.

What you need is simple practical advice on the easiest ways to monitor your measuring devices.

Quantity Control

The declaration of the net quantity of a food is mandatory. However you do have a number of options to choose from. The right scheme can save you cost and time, the wrong scheme can lead to an increase in waste.

The options available are:

Average weight, the ‘e’ mark, the average weight of packing run must be equal to or greater than the nominal weight.

Minimum weight, no pack can be less than the nominal weight.

Catch weight, each pack has it’s own, individual weight.

Count, product is not sold by weight but by number.

Each scheme has its own advantages and disadvantages. Selecting the right scheme is vital when starting a food manufacturing business.

Average weight control is a useful scheme but places a number of demands on a business. As a business owner you will need to understand Tolerable Negative Error and how to calculate the running average.

Average weight brings a lot of advantages. It also brings demands on control and record keeping. Getting this right will keep you on the right side of the legislation.

The 1 hour webinar discusses the various options. Explains how to mange each of them and how to make the right decision for your products and business.

Chemical Handling

Not a subject that immediately springs to mind when starting a new food business. However every food business has the requirement for cleaning and hygiene. This often includes the use of cleaning chemicals. This type of activity is regulated by The Control of Substances Hazardous Health Regulations.

Therefore as a business owner you need to understand what your obligations are and how to meet them.

In part 2 of this topic we will cover the other topics including making nutrition and health claims. What “free from” requires from a business and the specifics for modified atmosphere packing.

For more information please contact FBA.

Contact