This is part 2 of our series covering some of the issues that arise when starting a new food manufacturing business. In this post we will look at some of issues around making claims for your new products. We will also look at the requirements for on-line selling and the specialist rules on modified atmosphere packing. These are more of the Food Business Essentials.

You can select the webinars you need to gain the knowledge needed. After that you will be able to progress your business in the right direction.

What are these essential topics that you need to be familiar with when starting a new food manufacturing business?

Part 1

Part 2

- Food Safety

- HACCP

- Allergen Management

- Food Labelling

- Traceability

- Calibration

- Quantity Control

- Chemical Handling

Review the topics in Part 1 in the previous post.

Date Coding

Displaying the date or durability or shelf life is a mandatory requirement under the Food Information Regulations.

The regulations set out the specific text that must be used when date coding a food product. Only two options are permitted, the “Best before” and “Use by”.

As a business owner you must be familiar with the two options available and ensure you have selected the right scheme. You must also determine what is the shelf life of your product. Be aware; “use by” is about food safety and “Best before” is about product quality.

Make sure you understand the options and how to use them.

On-Line Selling

Referred to in the regulations as ‘Distance Selling” there are obligations for selling over the internet. All of the regulations relating to food manufacturing apply. You also need to ensure the mandatory food information is made available before the purchase is completed.

Distance selling is any systems where the consumer choses the product remotely. In other words it can be over the internet, through a catalogue or over the telephone.

If you intend to offer your products over the internet then you need to understand the specific obligations. “Everyone else is doing it” is phrase familiar to Enforcement Officers. Unfortunately it is neither an acceptable excuse or defence. Therefore, as a business owner, know what you should be doing.

Nutrition Claims

Making a claim about the nutritional composition or benefits of your product can be a useful marketing strategy. However the use of such claims is strictly regulated. You need to be aware of the requirements of the regulations before embarking on this strategy.

The Nutrition and Health Claims Regulations set out what is permitted. Only the 30 claims detailed within the regulation can be used. Each claim has sp[ecific conditions that must be met before it can be used.

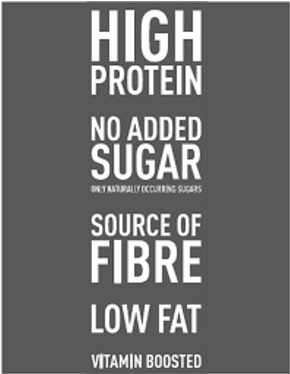

A claim is not just the text you use, you can imply a claim by the use of images or other statements. Which means you must carefully consider each statement you put on your product and marketing literature. We can examine the claims opposite in more detail.

High Protein

A high in protein claim or any statement that could be considered to mean the same can only be made when 20% of the energy value of the food is provided by protein. In other words it is not all about the amount of protein but what contribution it makes to the calorific value. Before knowing if you can make the claim you must calculate the % of the energy value that is derived from protein.

NO ADDED SUGAR

To make this claim your product must not have any mono- or disaccharides added to it. Basically no sugars. But the regulation goes further and does not permit the addition of any other ingredient used for its sweetening properties. In other words if you add honey to your recipe it is no longer free from added sugar.

Source of Fibre

Source of Fibre is a different calculation. To make this claim the product needs to contain a minimum of 3g of fibre per 100g of product, or, 1.5g per 100kcal. In this case the claim is related directly to amount present.

High in fibre is a different claim and this requires at least 6g of fibre per 100g of product.

If making nutrition claims is an important strategy when starting your food manufacturing business then you need to be familiar with the regulations. Our 1 -hour webinar will provide you with the basic guidance on making claims.

Health Claims

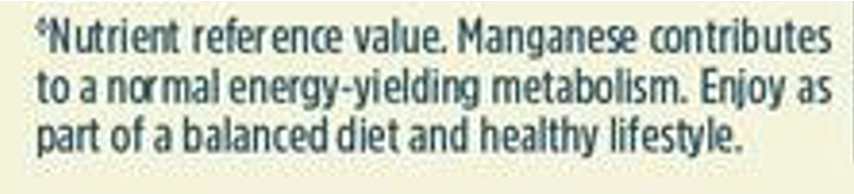

Often confused with nutrition claims, health claims are a very different prospect. Any statement that you make that suggests a link between your product and health is a health claim. But you cannot make a claim linking your product to a specific medical condition.

Health claims can be general or specific.

Above is an example of a specific claim based on the manganese present in the product. In order to make this claim the product must contain sufficient manganese to match the source of manganese nutrition claim.

General vs Specific Claims

A general health claim, in this case, could be “provides you with filling energy”. But a specific claim must support this. The manganese claim supports the general claim. Information that must be conveyed on the label can be another condition you have to meet.

The claim may be used only for food which contains 1 g of activated charcoal per quantified portion. In order to bear the claim information shall be given to the consumer that the beneficial effect is obtained with 1 g which should be taken at least 30 minutes before and 1 g shortly after the meal.

Register of Nutrition and Health Claims

Health claims are based on the claims permitted for the ingredients used and the levels present. When making health claims you need to review the list of authorised claims. You cannot rely on custom and practice.

Historical use can be confused with authorised claims. History does not always mean the claim is permitted. A search of the register for claims for ginseng shows currently no permitted claims when using this ingredient. This is despite a lot a support for the material.

The register contains 40,000 claims for various ingredients. Always check you are making an authorised claim. After which check your product meets the conditions for making the claim.

If making health claims are important when starting a food manufacturing business there is a lot to bear in mind. In other words health claims are not simple or straight forward.

Making “Free From” Claims

Many products use a “free from” claim. Whilst a strong marketing tool there are obligations you must be aware of. With the exception of gluten free there are no specific UK regulations covering this type of claim.

But this does not mean you are free to claim what you want.

General Food Law explains what can be considered an unsafe food product. The information which should be taken into account in this determination includes the label and marketing material. This means making a claim for allergen free when the product is not could make the product unsafe. In this way General Food Law regulates “free from” claims.

The advice from the Food and Drink Federation regarding Free From claims is;

A “free-from” allergen claim is an absolute claim. “Free-From”’ should only be used after a rigorous assessment of the ingredients, process and environment.

FDF Guidance on Free-From Allergen Claims.

When considering “Free-From” you will need to throughly review your manufacturing process. You need to risk assesses the process, the ingredients and the handling of the product.

If your factory uses allergens. Then how effective is your cleaning?

Have you validated and verified that your cleaning removes all traces of the allergen?

When can you not make a claim

The Food Information Regulation states:

Food information shall not be misleading, particularly by suggesting that the food possesses special characteristics when in fact all similar foods possess such characteristics.

Food Information Regulations

This means you cannot make a “free from” claim on a product when all similar products are “free from.”

Very much like all claims. “Free-From” is not simple or straight forward.

Nutritional Information

All pre-packed food must display the mandatory nutritional information unless the products are specifically exempt. There is also an exemption for Micro Businesses providing they meet certain criteria.

Food directly supplied by manufacturer of small quantities of products to the final consumer or to local retail establishments directly supplying the final consumer does not need to have nutrition labelling.

Food Information Regulations – Annex V

What does this exemption mean when starting a food business? In order to answer this we need to look at each section of the exemption.

What are Small Quantities?

It is the size of the business not the amount of product that defines small quantities. To be a Micro Business you should have:

Less then 10 full time equivalent employees

and

A turnover of less than £1.4 million

Most new business startups would comply with these conditions.

What does Directly supplied to the consumer entail?

This is supply direct to the consumer which can include selling over the internet.

However this must be direct to the consumer and not to another business outside your local area.

What are Local retail establishments?

Firstly the retailer must sell directly to the consumer. Then they must be locally to the manufacturing establishment. This is described as your county plus neighbouring counties or within 30 miles of the boundary of your county.

What if you sell to a retailer outside the defined local area?

Then they are not a local operation and you will need nutritional information on your product.

Where does Nutrition Information come from

The Food Information Regulations gives 3 options for how you can work out what the nutritional information is. These are the only options available to you.

- Manufacturer’s analysis of the food

- Calculation from the values of the ingredients used

- Calculation from generally established and accepted data

You can use any one of the techniques for your product. So what does each of them entail

Manufacturer’s analysis of the food

Exactly as it sounds, you send samples of your product to a commercial laboratory for analysis. You will need what is known as Cat2 nutrition. This will give you all the information need for your label. You decide how many samples you want to send. Remember there is a cost for each sample, but one sample may not be sufficient. There are some sampling techniques you can use to get the maximum benefit from the minimum number of samples.

When starting a food business you may want to consider the potential costs of analysis.

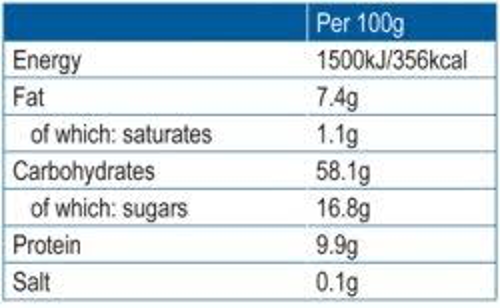

Calculation from the values of the ingredients used

A very costs effective way of determining the nutritional information. A very practical way for a small business.

You need to have a specification or at least the nutrition information for every ingredient that you use.

Then from your recipe you can calculate the contribution each ingredient makes to the overall levels. Finally you can apply the conversion factors to determining the energy value.

The process can be time consuming, but it only costs your time. Make sure you keep a copy of your calculations.

Calculation from generally established and accepted data

Possibly the least effective of the 3 options.

The most widely accepted data in the UK is McCance and Widdowson’s the Composition of Foods.

You can buy a copy of the book or access the data, free of charge, through the Composition of Foods Integrated Dataset (CoFID) available from the FSA.

The problem with CoFIDs is that you are unlikely to find data that relates directly to your product or recipe. You must not copy the data from a similar product even if you think it is close.

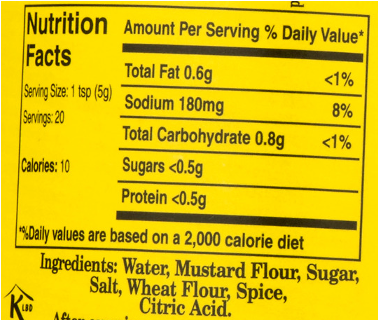

What must be declared?

The regulations set out what information must be displayed and in what order.

You have no freedom about what you want to include.

You are free to include some additional nutritional information, but you must include the elements above. Presenting the data as a table is the preferred format.

Modified Atmosphere and Vacuum Packing

These are specialist packing techniques for certain products. If you are planning to use these techniques you need to be aware there are specific rules that apply under certain conditions.

Labelling

The phrase ‘packaged in a protective atmosphere’ must be used on any product where packaging gases are used. The specific gas or gas combination too not need to be listed.

Shelf Life

The main purpose of MAP and VAC packing is to extend the shelf life of a product. However chilled product that is MAP/Vac packed is limited to a 10 day shelf life unless additional controlling factors are in place.

All raw and ready to eat foods that are MAP/VAC packed and stored chilled are covered by the guidance. A copy of the guidance is available from the Food Standards Agency.

If you pack you products using these techniques then you should obtain a copy of the guidance and ensure you are meeting the requirements. If this is packaging format you are considering using when starting your food business you must bee familiar with the rules.